3 Things You Didn’t Know About the PT6A Engine

The PT6A Design Solved a Crucial Problem in Maintenance Procedures

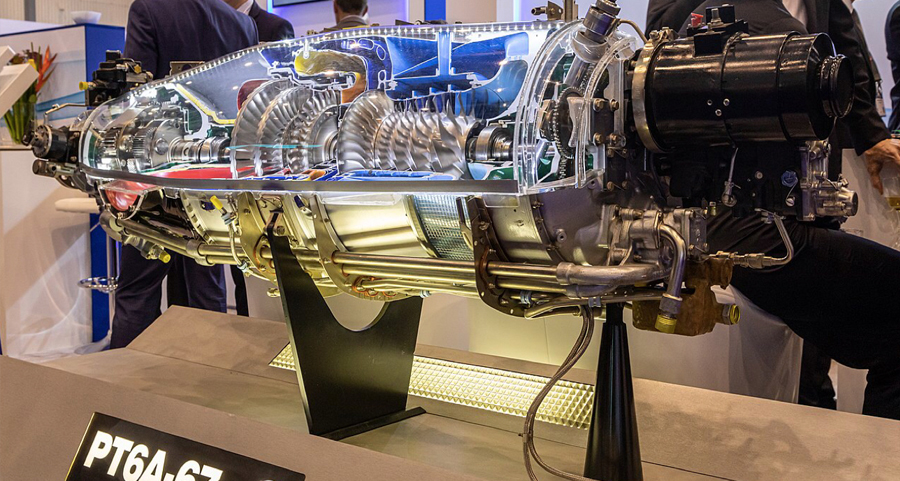

Gas turbine engines are composed of hot-running parts and cool-running parts. Within current technology this physically cannot be avoided, and the result is an imbalance in part deterioration; the hottest parts need to be repaired and replaced more often than the coolest parts. Having to remove the entire engine from an aircraft and disassemble it in order to get to the hottest parts is a lengthy and expensive process. The achievement of the PT6A did away with the need to remove the entire engine by placing the hottest parts, the combustion chamber and gas generator turbine, at the propeller end of the aircraft. They can be removed without disrupting the rest of the engine and its connections. Chief Designer Allan Newland patented this arrangement; he was one of the original ‘Dirty Dozen’ who created the iconic turboprop. All adaptations of the engine consist of two basic sections that can be easily separated for maintenance and repairs.

Until the development of the Pratt & Whitney PT6A, most aircraft engine intakes were positioned at the front end of the vehicle. A PT6 installation is mounted with the intake toward the rear, making it known by many as the “back-to-front” engine. This ensures the power section is at the front of the nacelle, driving the propeller directly without the need for a long shaft. Two exhaust outlets are aimed astern, and intake air is fed to the engine through an underside mounted duct. This setup assists maintenance by permitting the power section to be removed, propeller and all, and exposing the gas generator section. There are a few special installations, such as the PT6A-66B in the Piaggio Avanti P180 where the engine is reversed, making the propeller act as a “pusher” with the accessory gearbox positioned toward the front.